Years of Experience

-

Growing

Since 1975

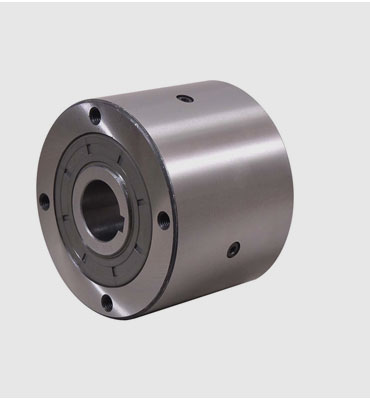

State of the art facility to give the best of product line. -

Legacy

Of Expertise

With three decades of rich experience. -

Growing

Since 1975

State of the art facility to give the best of product line. -

Legacy

Of Expertise

With three decades of rich experience.